Technical treatise on furnishing textiles

DISCOVER IN THIS ARTICLE

This booklet does not claim to be exhaustive, but aims to help you understand how the products we sell are manufactured, so that all of you who are confronted with technical requests on a daily basis can respond in a simple manner without going into detail. We're going to tell you about :

- Textiles in general

- Different materials

- Weaving

- Different media

- Finishing (dyeing, printing, coating)

- Clothing

TEXTILES IN GENERAL

In our everyday lives, we all use textile articles for dressing, sleeping, washing and so on. This makes textiles one of the most important sectors, but also one of the widest. Whether for furnishing, clothing, bed linen, bath linen or outdoor wear, the uses are as varied as the technical characteristics of each material.

Discover the technical features of our products, to help you choose and make your own.

To begin with, there are two main categories of fabric:

- MAILLE is a fabric knitted in the same way as our grandmothers did, and found in sweaters, scarves, socks, pyjamas, some underwear, etc....

- CHAIN AND WEFT: used extensively in clothing, with shirts, pants, coats etc.... and is the essential structure of our home products. We'll take a closer look at how warp and weft is woven, its various applications, and its different supports.

THE MATERIALS

Various materials are used in the production of our products, led by cotton with 90% of our assortment, but also polyester, acrylic, bamboo viscose and other materials that we'll mention briefly.

There are three main categories of materials: natural, artificial and synthetic. NATURAL materials include plant-based materials (cotton, linen, jute, etc.) and animal-based materials such as wool from sheep, mohair or angora goats, or silk extracted from the bombyx silkworm.

ARTIFICIALS come from natural sources, but are transformed by man. Fibers are extracted from the cellulose present in wood or other plant matter, then chemically transformed into yarns. These yarns can be used to create fabrics with properties such as softness and shine. The most widely used artificial materials are viscose and acetate.

SYNTHETICS, on the other hand, are manufactured entirely in the laboratory from chemicals, often derived from non-renewable resources such as petroleum. Synthetics can have interesting properties such as elasticity, waterproofing, strength, wrinkle resistance, heat transfer, etc. Common synthetic textiles include polyester, nylon and elastane (polyurethane-based).

WEAVING

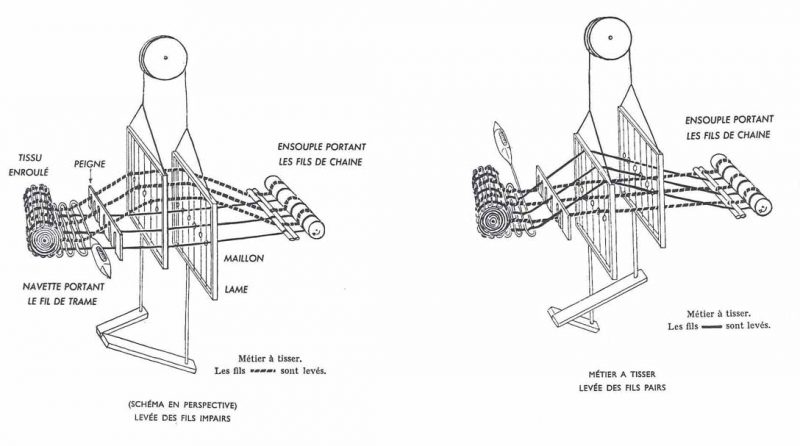

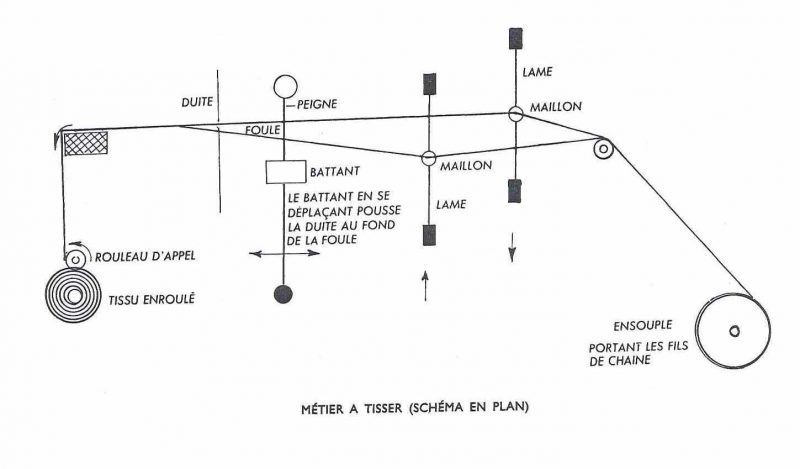

The weave we're interested in is a warp-and-weft weave. The images below show the various components of a loom.

There are different techniques for interweaving warp and weft threads, known as ARMURE. There are three basic weaves: plain, twill and satin. From these three weaves derive declinations, combinations and special weaves that form numerous fabrics.

TOILE weave, also known as drap, is the oldest and simplest weave. It's the one we use for our cretonne and coatings, among others. Plain weave is obtained by alternately lifting the even and odd yarns of the warp, to allow the weft yarn (duite) to pass through. All fibers can be woven in plain weave. The resulting fabrics have neither obverse nor reverse sides.

ENNOBLING

This term refers to all treatments used in the textile industry to improve the appearance, texture and properties of fabrics.

For us, the first operation is bleaching. This allows us to obtain very vivid colors later on. The technique is simple, using hydrogen peroxide. Next come the various printing and dyeing techniques.

FINISHED PRODUCT

Discover also

STOF joins the JJA Group

By joining this ambitious group, STOF is joining a solid, trusted company, while remaining true to its values.

Read more